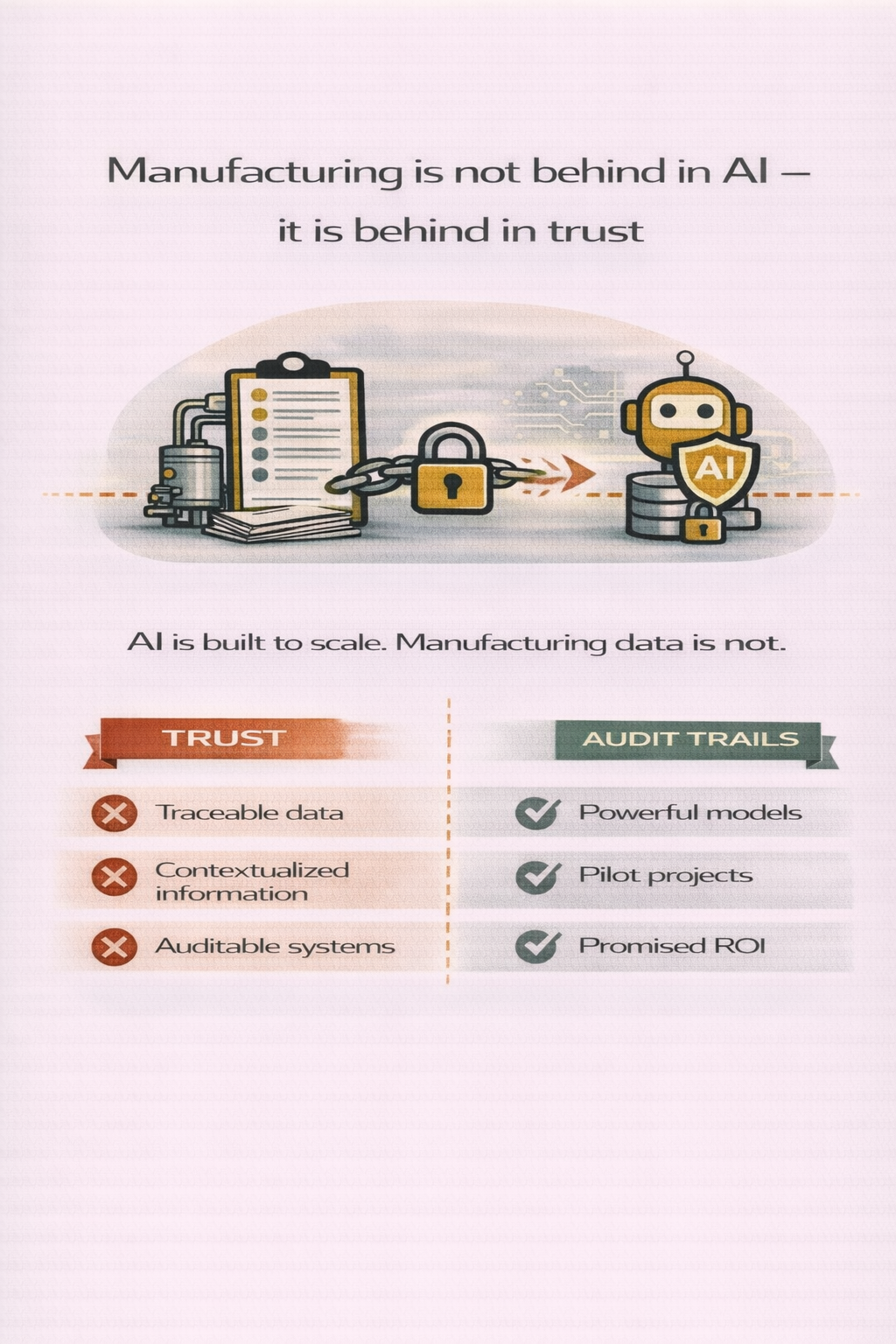

Manufacturing is not behind in AI – it is behind in trust

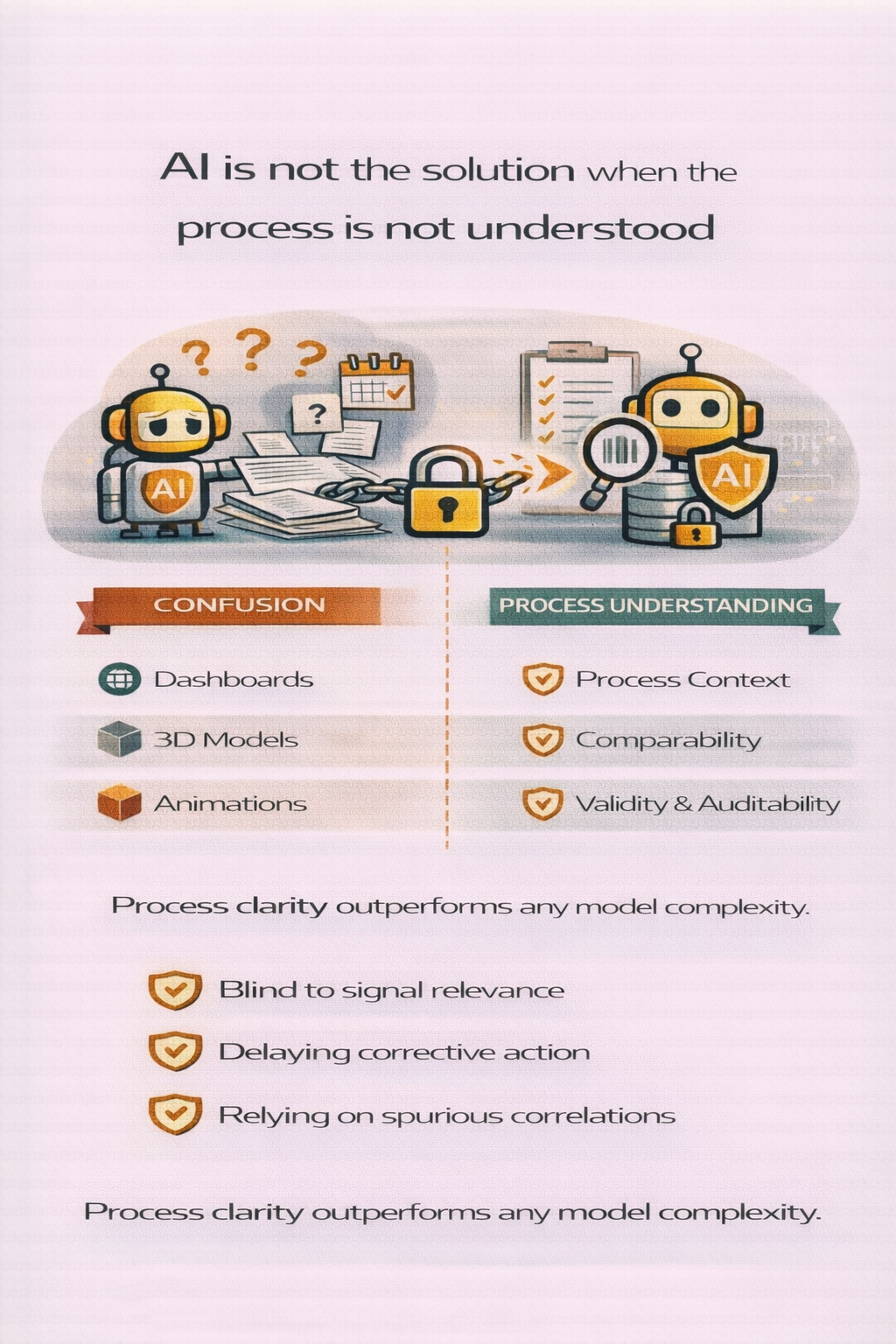

Working in regulated manufacturing shapes how you think about data.

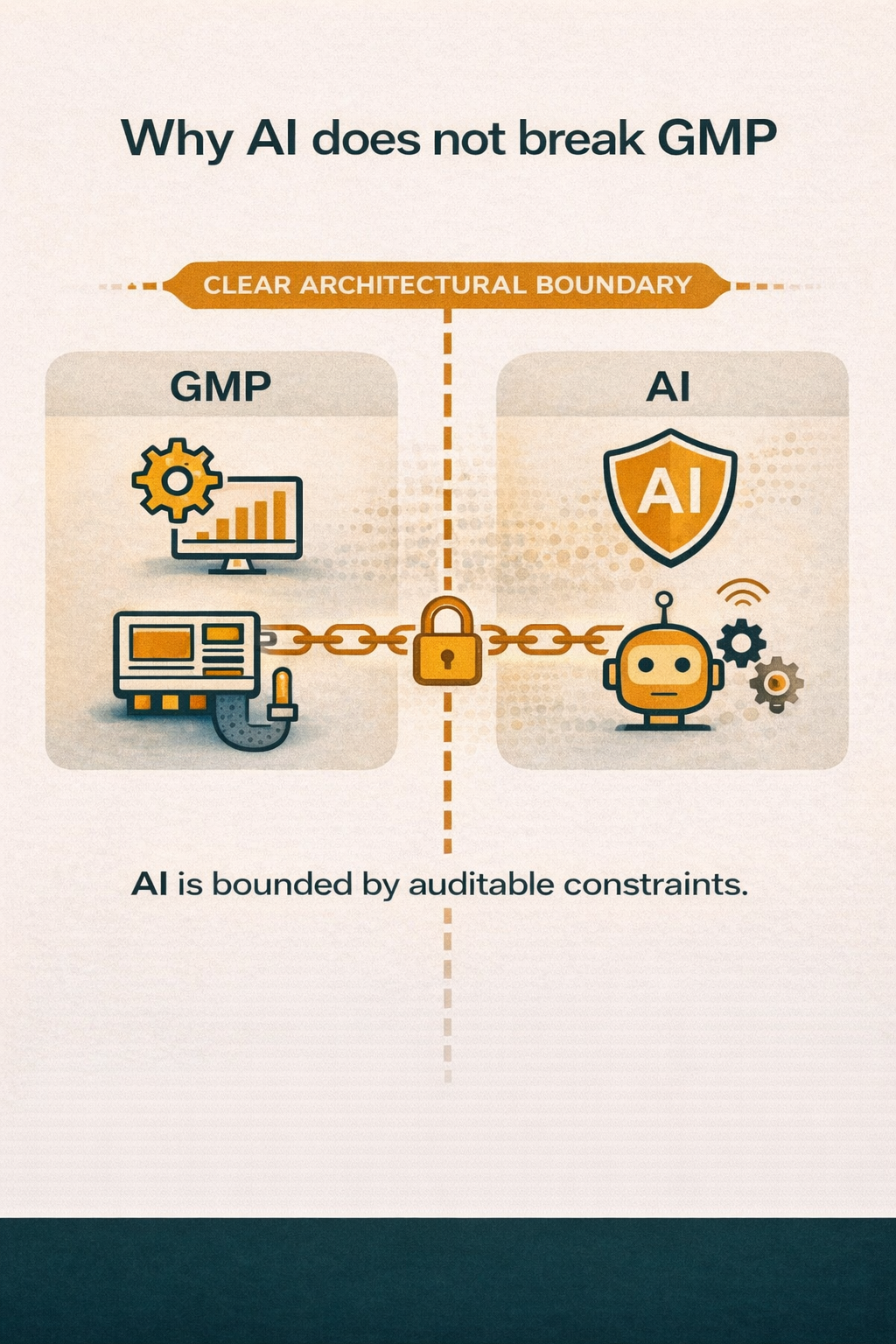

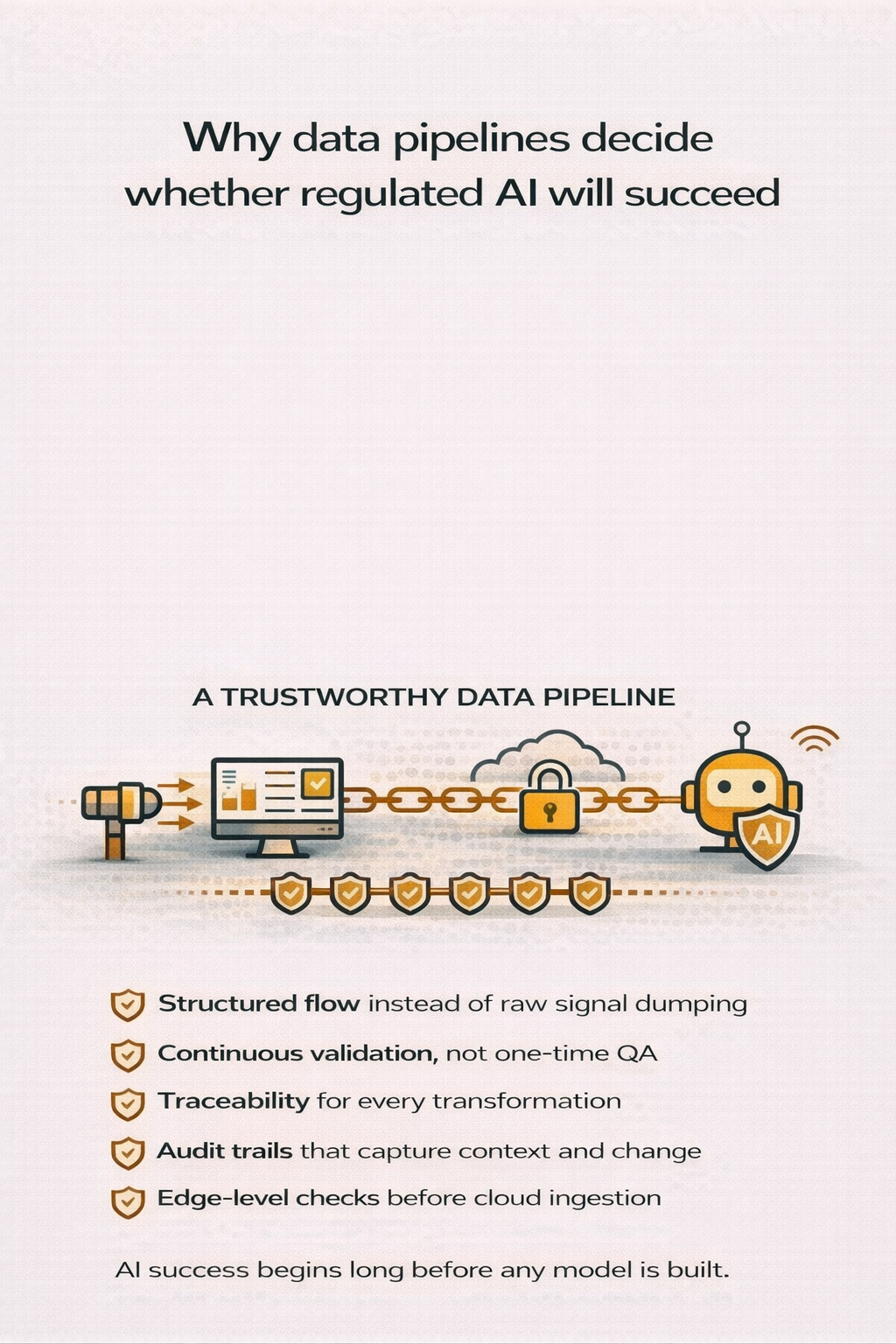

You cannot change a parameter without documentation. You cannot move data without traceability. You cannot trust an output without understanding its full context.

From this perspective, the AI discussion in manufacturing feels oddly misplaced.

Models are not the bottleneck

AI models are not the problem.

They are easy to build. Quick to deploy. Increasingly commoditized.

What blocks progress is everything around the model.

The underlying data is often:

- not validated

- not contextualized

- not traceable across machines, shifts, or batches

- not auditable in a way regulated environments require

Why AI stays in pilot mode

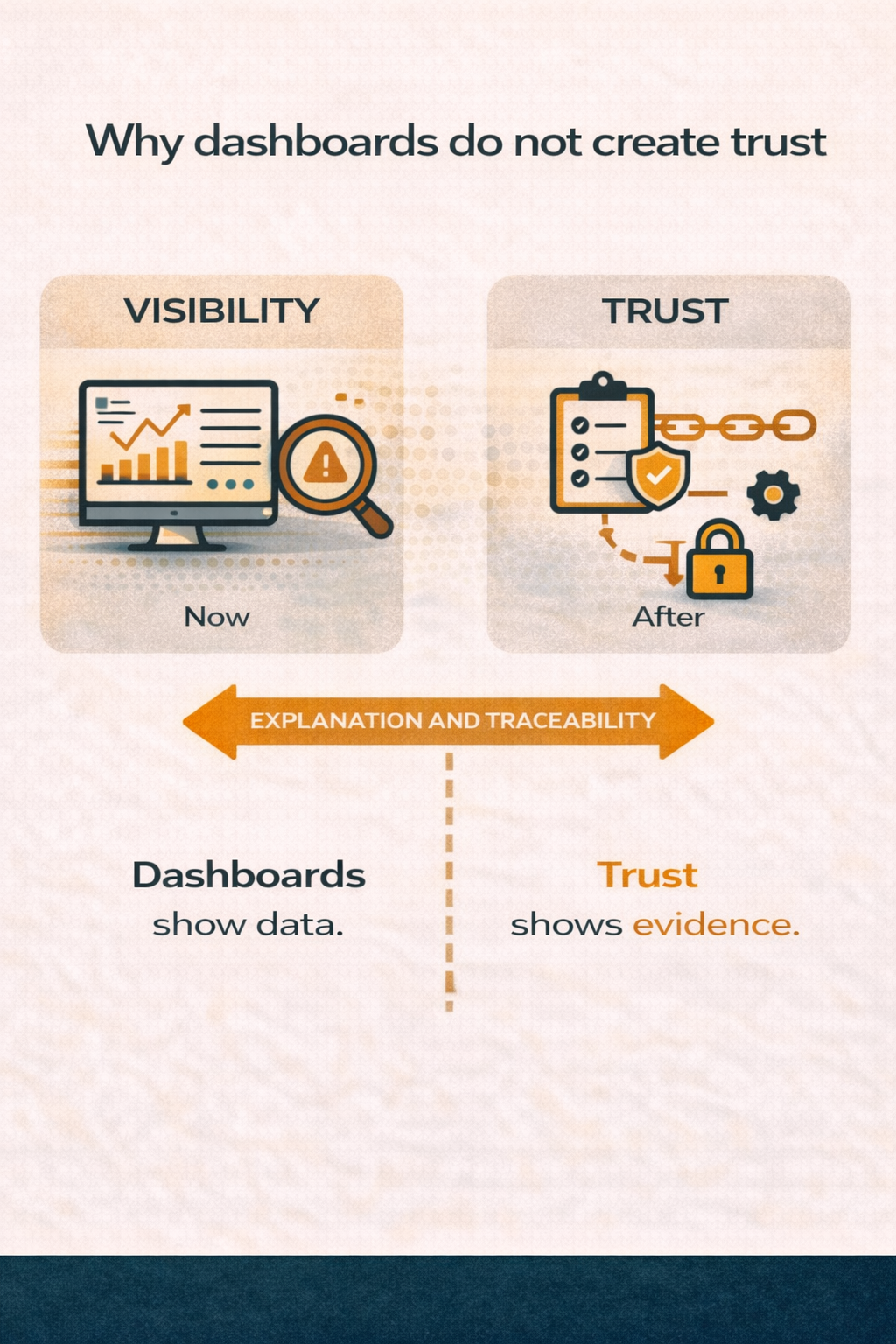

Without trust, AI never scales.

Predictions may look promising. Dashboards may show improvements. But the moment results matter, confidence collapses.

Once trust, context, and auditability are solved, ROI appears immediately. This pattern repeats across sites and industries.

Trust cannot be added after automation.

AI only scales when trust scales.